What Are Concrete Strength Classes? Strength Differences and Application Areas

by Rabia Tosun - October 29, 2025Concrete is an indispensable part of the construction industry. However, not all concrete types are suitable for every structure. That’s where concrete strength classes come into play. Classes such as C20/25, C25, C30, and C35/45 define the compressive strength of concrete and determine where it can be used.

In this article, we’ll clearly explain what concrete classes mean, how their strength levels differ, and which type is used in which structure. Whether you’re a contractor, an architect, or a homeowner building your own house, these insights can make a major difference in the safety of your structure.

Yükselen Mimari, as a construction company based in Antalya, provides engineering solutions that prioritize structural safety. In every project, it aims to build durable and long-lasting structures through the correct selection of concrete strength classes.

What Is a Concrete Strength Class?

A concrete strength class is a technical classification determined by the compressive strength the concrete achieves after 28 days. The letter “C” stands for Concrete; the numbers following it represent the strength values measured on cylindrical and cubic test samples in megapascals (MPa). These values define the load-bearing capacity of the concrete and indicate which types of structures it is suitable for.

How is this classification made?

A concrete class typically begins with the letter “C,” followed by two numbers, such as “C25/30.” Here:

- C means Concrete

- The first number represents the 28-day compressive strength measured on a cylindrical sample (in MPa).

- The second number represents the compressive strength measured on a cubic sample.

These values are determined through laboratory testing of concrete samples under compression.

Why Is It So Important?

Because choosing the wrong concrete class directly affects structural safety. For instance, while C20/25 may be sufficient for a ground-floor residence, high-strength concretes such as C35/45 should be used in bridge piers or multi-story buildings. Selecting the appropriate concrete class is not merely a technical detail — it is a fundamental element of structural safety.

To gain a deeper understanding of how reinforced concrete systems work and the role of columns in load-bearing capacity, you can also read our article titled “What Is Reinforced Concrete? The Importance of Columns in Structural Safety.”

At Yükselen Mimari, we emphasize that selecting the right concrete class in every project is not only an engineering necessity but also a matter of human safety.

What Are Concrete Strength Classes?

Concrete strength classes measure how resistant a concrete mix is to compressive stress. According to the TS EN 206 standard, classes are typically denoted with two numbers (e.g., C25/30, C30/37). The first number indicates the cylindrical strength, and the second shows the cubic strength. As strength increases, concrete becomes more durable but also more difficult to work with.

The technical data in this article have been prepared in line with the TS EN 206-1 Concrete Standard and TBDY 2018 Regulation. All information is based on current engineering principles and verified laboratory test data.

What Do the Letters and Numbers Mean?

In concrete class notation, the “C” stands for Concrete. The accompanying numbers mean:

- First number: Compressive strength of a 150 mm × 300 mm cylindrical sample (in MPa).

- Second number: Compressive strength of a 150 mm × 150 mm × 150 mm cubic sample (in MPa).

These tests measure when the concrete sample fails under load, showing its durability.

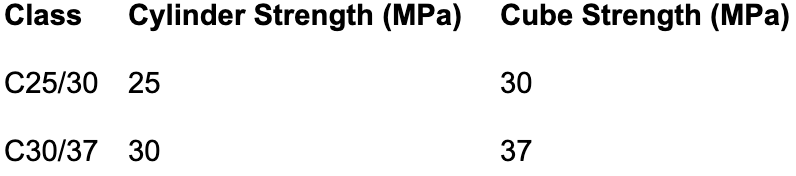

Example:

- C30/37 means 30 MPa cylinder strength and 37 MPa cube strength.

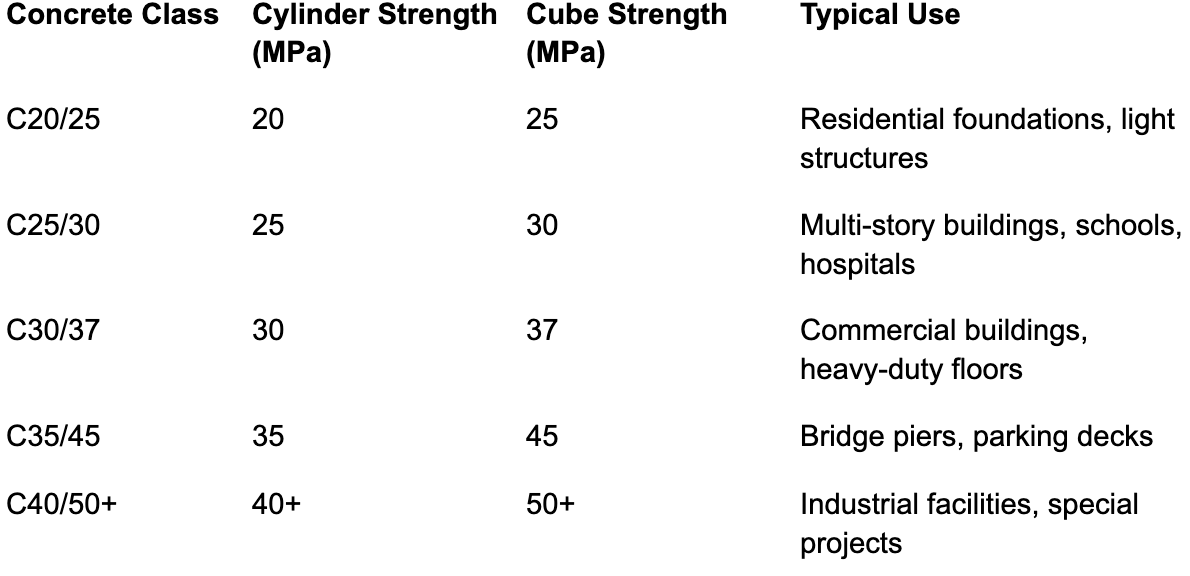

Common Concrete Strength Classes

Note:

- As strength increases, cost and workability challenges also rise.

- Using unnecessarily high-strength concrete is economically inefficient.

At Yükselen Mimari, we always stress that choosing the most suitable, not the strongest, concrete is the smart approach.

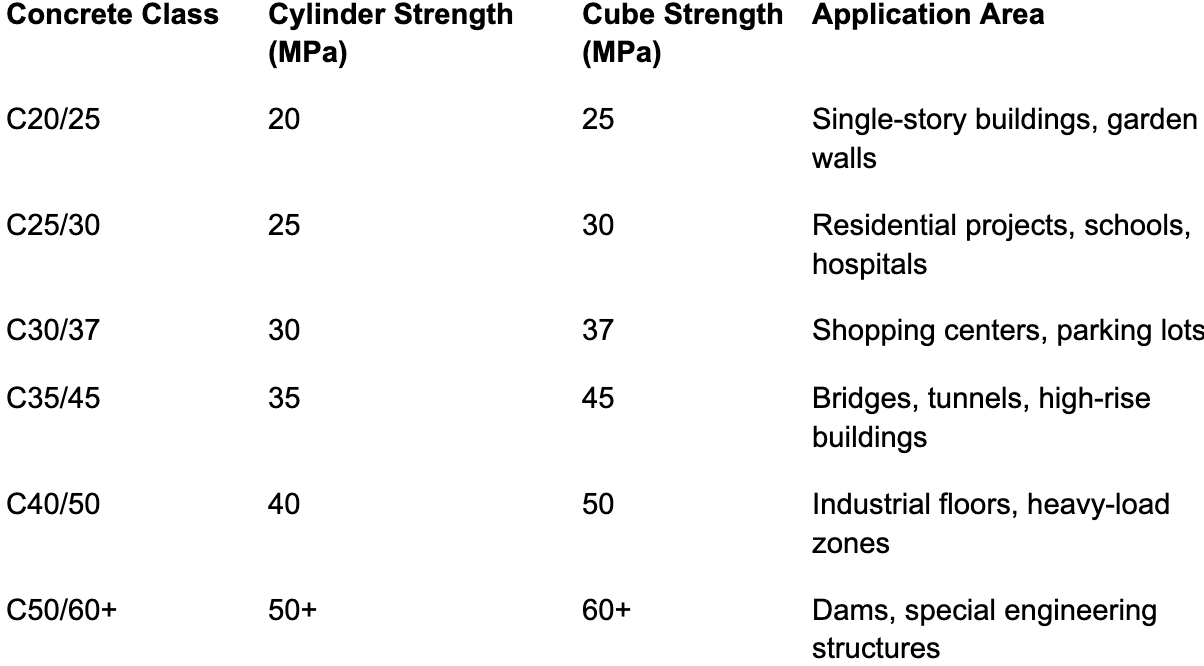

Concrete Strength Class Table

How to Interpret the Table:

- Cylinder and cube tests produce different results; both are used for accuracy.

- Higher class ≠ always better; selection must match structural needs.

- All listed classes comply with TS EN 206 and TBDY standards.

Yükselen Mimari ensures accurate technical communication for clients and project teams balancing safety, cost, and efficiency.

What Do C20/25, C25, C30, and C35/45 Mean?

These international codes indicate concrete strength levels. “C” stands for concrete; the first number refers to the cylinder test, and the second to the cube test. For example, C25/30 has 25 MPa cylinder and 30 MPa cube strength. The higher the class, the greater the load-bearing capacity.

Explanations of Common Grades

C20/25

- Use: Garden walls, small foundations, light structures.

- Advantage: Affordable and easy to apply.

- Caution: Not suitable for heavy loads.

C25/30

- Use: Residential, schools, mid-load projects.

- Advantage: Excellent cost-performance ratio.

- Note: Most commonly used in Turkey.

C30/37

- Use: Multi-story buildings, parking decks, malls.

- Advantage: High load capacity.

- Note: Requires precise curing and casting.

C35/45

- Use: Bridges, tunnels, seismic zones.

- Advantage: High strength and durability.

- Note: Requires expert handling and higher cost.

Concrete Classes by Application

Residential Projects (C20/25–C25/30)

- Ideal for single-story or small-scale houses.

- C25/30 is the most common class in Turkey.

Commercial and Multi-story Structures (C30/37–C35/45)

- Suitable for offices, malls, and parking structures.

- Designed for higher static and dynamic loads.

Infrastructure & Engineering Works (C35/45 and above)

- Used in bridges, tunnels, viaducts, and dams.

- Offers superior resistance to pressure, impact, and environment.

Seismic Zone Construction

- Minimum C25/30 recommended by TBDY 2018.

- Higher classes may be required for critical structures.

Industrial Projects

- C40/50+ for factory floors and heavy machine foundations.

Difference Between C25 and C30

- There is roughly a 5–7 MPa difference, allowing for higher load capacity. C25 suits most residential uses; C30 is safer for taller or seismic structures.

Cost: C30 is about 5–10% more expensive but offers better safety and longevity.

How Concrete Strength Classes Are Determined

Laboratory Testing:

- Samples are taken from fresh concrete.

- Cured for 28 days at 20 ± 2 °C and 95% humidity.

- Then subjected to compressive strength testing.

Design Calculations:

- Based on structural loads, soil type, and environmental factors.

- Engineers use static analysis to determine class requirements.

Standards:

- TS EN 206-1 – defines strength and testing methods.

- TBDY 2018 – regulates minimum seismic zone requirements.

- TS500 – defines reinforced concrete design rules.

Of course, the quality of application during the casting process is just as important as choosing the correct concrete class. Errors made during the preparation, transportation, or placement of concrete can reduce the performance of even the highest-grade material.

To learn more about this topic in detail, you can explore our guide titled “How Is Concrete Casting Done? Common Mistakes and Application Techniques.”

Yükselen Mimari’s Approach

For every project, Yükselen Mimari evaluates:

- Soil investigation

- Structural analysis

- Intended use

- Climate and seismic risk

When necessary, we conduct laboratory testing and site supervision to ensure full compliance.

Just like the foundation of your project, choosing the right concrete class is the foundation of trust. If you want your structure to be long-lasting, durable, and fully compliant with regulations, as Altıntaş Construction, we manage every stage of your project from soil analysis to concrete casting with engineering assurance.

Get in touch with the Yükselen Mimari team to determine the most suitable concrete class for your structure together.